Your Leader In Porous Metal Filters

Capstan is a leading supplier of porous metal filters worldwide. Capstan Filters are well known for high performance porous sintered metal filters, in stainless steel, bronze, or nickle alloys, for liquid or gas filtration.

We have been developing and manufacturing sintered metal since the 1950s. Today, we are one of the world’s market leaders for sintered metal filters, with production taking place in North America and sales around the world.

Liquid & Gas Filtration/Separation

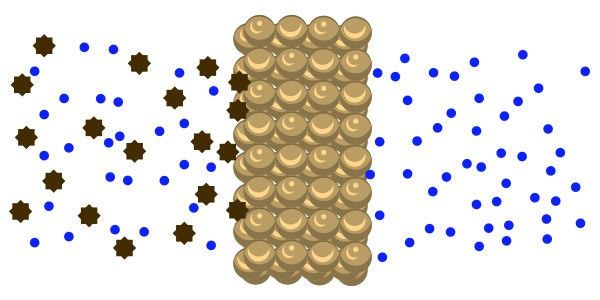

Capstan filters are able to reduce or completely remove particulate matter from either a gaseous or liquid medium. Particulate matter can include, but is not limited to, suspended particles (sediment, metal chips, salt, ect), algae, bacteria, fungi spores, and unwanted chemical/biological contaminants. Capstan filter pore sizes range from 0.2 µm – 250 µm.

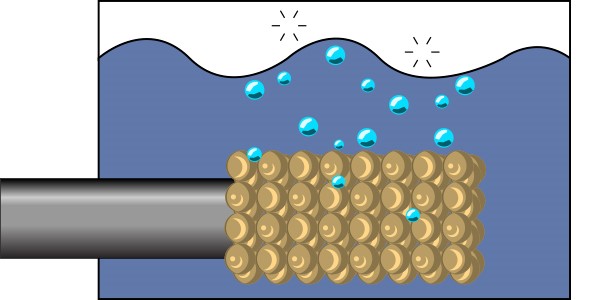

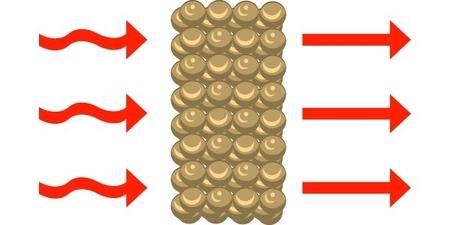

Spargers

Examples of Sparging Applications:

- Soda Carbonization

- Beer Carbonization

- Oxygen Stripping of Edible Oils

Sparging is the introduction of a gas into a liquid. It is used to either remove an unwanted dissolved gas (oxygen stripping) or dissolved volatile liquid. It can also be used to introduce a gas into a liquid (carbonization). Traditional sparging created bubbles with a diameter of 6 mm. PM filter sparging allows for even smaller bubble diameter, thus increasing surface area of the bubbles creating a more efficient sparging application by decreasing process time.

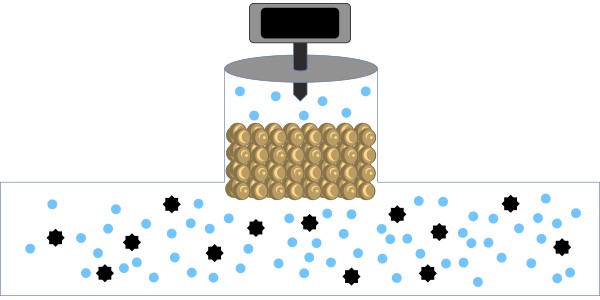

Breather Vents

Capstan filters are often used as breather vents in cylinders, gear boxes, manifolds, hydraulic systems, reservoirs, and other systems. Breather vents allow for pressure equalization and allow air/gas in and out of a system while blocking particulate matter from entering the system. Metal filters can be backwashed to remove particulate matter giving it a longer lifespan as a breather vent than other filter media.

Sensor Protection

Filters can be used to protect electronic components, thermometers, various sensors, key components of medical systems, and other sensitive products from water, liquids, sediment, dust, as well as pressure fluctuation. Capstan has sensor protection filters on the Mars Curiosity Rover to protect various sensors from the very fine, infamous Mars dust.

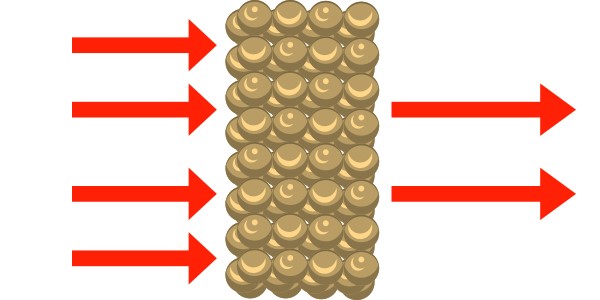

Flow Control (Throttling/Dampening)

Capstan filters can be used to control the flow within an air, gas, vacuum, and fluid flow system. The filter’s uniform pore sizes allow for consistent, repeatable flow regulation and can also protect valves, sensors, and anything else downstream in the system from contaminants. Flow control is used in such applications as pneumatic timers, gas supply control elements, and time delay elements in automotive applications.

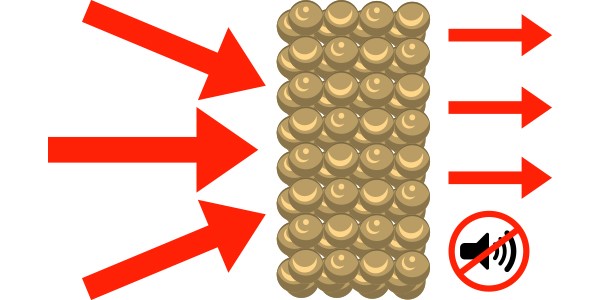

Exhaust Silencers

Capstan filters can be sinter-bonded to any required fitting allowing it work as an exhaust silencer. The filter works to not only protect solenoids and manifolds from getting contaminants inside the system but it also minimizes the noise level of exhaust coming out of the system. The exhaust silencer filters also lower the amount of air blowing out of the system which minimizes contaminants wafting protecting surrounding equipment.

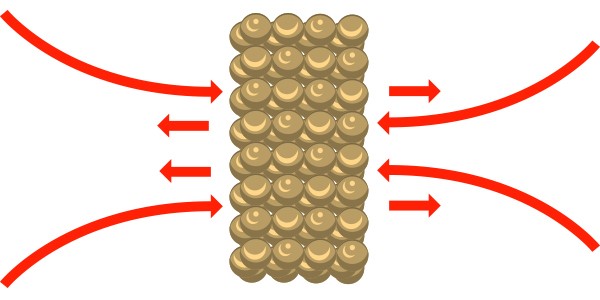

Flow/Pressure Equalization

Capstan filters can be used to equalize and control the flow rate and pressure in a system. Equalization protects systems against a surge of liquid and creates a uniform flow as the gas or liquid moves across the uniform pores.

Capstan’s porous metal filters can be used in a wide array of applications across all industries. Capstan filters can be used to filter/separate, to throttle/dampen flow, dispersion of gas/liquid, and to equalize flow.

Capstan filters are used in for medical devices, scuba gear, beverage filtration, defense products, and can even be found on the Mars Curiosity Rover! Yes, we have filters in outer space!

Common Applications of Capstan Filters

- Silencers

- Aerosol Separation

- Spargers

- Sensor Protection

- Valve Protection

- Dispersion Filters

- Food/Beverage Processing

- Able to withstand extreme environments; high/low thermal levels, high pressure, impact/stress loading.

- Oxidation Resistance to gasoline, benzol, carbonic acid, tetrachloride, trichloroethylene, and all types of oil

- Operating Temperature Range: -400 to 900 degrees Farenheit

- Large Variety of Pore Sizes on Offer

- Resistance in basic and acidic environments

- Ability to reverse flush and other processes to clean filters

- Competitive pricing

- Structural stability

Capstan produces bronze metal filters through gravity sintering techniques. The bronze powder is poured and packed into moulds and then placed in a low-temperature furnace.

Stainless steel filters are maufactured via the standard Powder Metal Process using mechanical presses and custom built tool sets to produce near-net shape “green” parts. These “green” parts are fragile before the sintering process but after the sintering process they are stronger than nearly all conventional filters.

The sintering process bonds the metal powder by bringing the product to just below its melting point, allowing fusion of the powder granules. The granules connect via a “neck-connection” leaving porous holes in the part thus creating our metal filter. This process also makes the filter stable and hold the properties of metal (i.e. high thermal resistance, ability to withstand rapid thermal changes, high pressure resistance).