As the Pandemic continues across the globe and COVID-19 cases are still on the rise, there is high demand for ventilators, personal protective equipment, and other various medical equipment needed to keep our global population healthy. Before the pandemic, Capstan California has played an important role in providing medical components and powder metal filters. These filters are used in many medical applications including, but not limited to, ventilators, oxygen blenders, medical gas delivery systems, and syringe filters.

As the number of COVID-19 cases started to rapidly grow within the United States, existing ventilator manufacturers were struggling to keep up demand for these vital machines.

Even with all ventilator producers working above their full capacity, there is still a need for even more ventilators. General Motors, Tesla, and Ford all took it upon themselves to assist in the fight against the pandemic by retrofitting their existing manufacturing equipment to produce ventilators instead of automobiles.

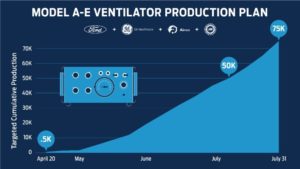

Due to Capstan’s prior experience providing porous metal filters used in ventilators, Ford selected Capstan as one of their vendors to assist in producing 50,000 ventilators in 100 days. Capstan and other essential manufacturing businesses have worked together since early April to meet this demand and beyond. The ventilator production is well underway, with Ford expected to deliver finished product in just a few weeks.

Capstan is proud to assist Ford and other medical equipment producers with high quality, porous metal filters in a timely fashion during this global pandemic. Being able to help keep our nation and globe healthy and breathing is of utmost importance to the team at Capstan California and we will continue to provide quality filter components until this pandemic has ended and beyond.